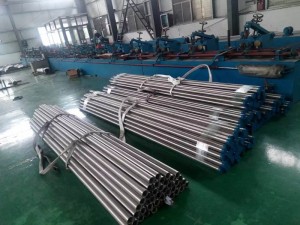

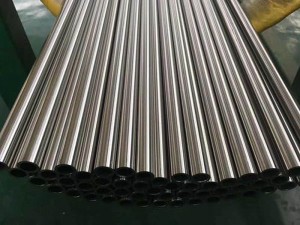

Tlhahiso ea li-tubes tse fapaneng tse hlakileng tse khanyang

Pipe ea Precision ke mofuta oa phala ea tšepe e se nang seam e nang le ho nepahala ho phahameng le khanya e phahameng e hlahisoang ke setšoantšo se batang kapa mokhoa o batang oa ho roala. Bophahamo ba eona ba kahare le kantle bo ka nepahala ho isa ho 0.2mm. Ha e netefatse feela ho kobeha le matla a torsional, empa hape e na le boima bo bobebe. Ka hona, e sebelisoa haholo ha ho etsoa likarolo tse nepahetseng tsa mochini le meaho ea boenjiniere. E boetse e sebelisoa hangata ha ho etsoa libetsa tse fapaneng tse tloaelehileng, barrel, shell, bearing, joalo-joalo.

Lisebelisoa tse tloaelehileng ke 10#, 20#, 35#, 45#, 20Cr, 40Cr, 20CrMo, 16Mn, 27SiMn, 304, 201, 310S, tšepe ea boleng bo phahameng ba carbon structural.

1. E nyane bophara ba kantle.

2. Ho nepahala ho phahameng mme ho ka sebelisoa bakeng sa tlhahiso ea li-batch tse nyane.

3. Lihlahisoa tse huloang ke serame li na le ho nepahala ho phahameng le boleng bo botle ba bokaholimo.

4. Sebaka sa sefapano sa pipe ea tšepe se rarahane haholoanyane.

5.Pipe ea tšepe e na le ts'ebetso e phahameng le tšepe e teteaneng. Mokhoa oa ho hlahloba o ka sebelisa metsi a sesepa ho hlakola manonyeletso a sebōpi sa annealing ho bona hore na ho na le ho lutla ha moea; Har'a tsona, sebaka seo khase e ka balehang ho sona ke sebaka seo sebōpi sa annealing se kenang le ho tsoa ho sona. Lesale la ho tiisa sebakeng sena le bonolo ka ho khetheha ho apara, kahoo le lokela ho hlahlojoa le ho nkeloa sebaka khafetsa. Morero oa ts'ebetso ea ho lokisa phala e nepahetseng ea tšepe pele ho kobeha ho batang; Liphello tsa mocheso o tloaelehileng, nako ea ho tšoara le mokhoa oa ho pholisa ho microstructure le thepa ea mechine ea pipe ea phepelo e ile ea ithutoa le ho hlahlojoa; Mokhoa o tloaelehileng oa ho tloaeleha oa phala e nepahetseng ea tšepe e ikemiselitse: mocheso oa mocheso ke (890 ± 10) ℃, le ho pholile ha moea o hasaneng ka mor'a ho tšoara 6min. Ts'ebetso e tloaelehileng ea ho tloaeleha e ka felisa ka ho feletseng sebopeho sa widmanstatten ea phala e nepahetseng ea tšepe, ea etsa hore ho bapisa matla a lihlahisoa le matla a tsitsitseng ho be bonolo haholoanyane, le ho ntlafatsa tekanyo ea matla a lihlahisoa σ S/b σ ≤ 0.78, elongation 5 δ ≥ 30%, e ntlafatsa haholo serame ho etsa tshebetso le ho qoba batang kobang cracking. Coefficient ea katoloso e ka hlalosoa ka molumo kapa bolelele, hangata ka bolelele. Boima ba boima ba ntho ke boima ba yuniti ea ntho, ka kg / m3 kapa 1B / in3. Khatello e setseng ea tsitsipano e tsoa haholo khatellong e setseng e hlahisoang ke lisebelisoa nakong ea welding.

Hajoale, annealing ka mor'a ho futhumatsa tjheseletsa e sebelisoa haholo boenjiniere ho felisa khatello ea maikutlo e setseng, 'me ho pholisa ka mor'a welding ke mokhoa oa bohlokoa oa ho hlahisa khatello ea maikutlo. Mokhoa ona ha o senye matla feela, empa hape o hlahisa habonolo khatello e kholo ea masala a welding. Kalafo ea mocheso oa post weld ke theknoloji e ncha ea ho felisa khatello ea kelello e setseng. Peipi e nepahetseng ea tšepe e tla be e futhumetse mocheso oa mocheso oa poso pele ho tjheseletsa, 'me weldment e tla tsoela pele ho futhumatsoa ho boloka mocheso ona nakong ea ho cheselletsa. Ka mor'a ho cheselletsa, e tla kenngoa ka k'hothone e sireletsang ho e pholisa butle. Ho tima ho ka eketsa matla le boima ba phala ea tšepe, empa ho fokotsa polasetiki ea eona. Lisebelisoa tsa ho tima tse atisang ho sebelisoa ho tima li kenyelletsa metsi, oli, metsi a alkaline le tharollo ea letsoai. Ho futhumatsa ha phala e nepahetseng ea tšepe ho futhumatsa phala ea tšepe e tingoeng ka mokhoa o nepahetseng ho isa mochesong o itseng ebe oa e pholisa ka mokhoa o itseng, o bitsoang tempering. Sepheo ke ho felisa khatello ea kelello e ka hare e hlahisoang ke ho tima, ho fokotsa ho thatafala le brittleness, le ho fumana thepa ea mechine e lebelletsoeng. Tempering e arotsoe ka mocheso o phahameng oa mocheso, mocheso o mahareng le mocheso o tlase oa mocheso. Hangata Tempering e sebelisoa hammoho le quenching le normalizing. Phekolo ea ho tima le ho futhumatsa mocheso oa mocheso o phahameng oa mocheso ka mor'a ho tima o bitsoa phekolo ea quenching le tempering.